Dimpling Right Wing Skeleton

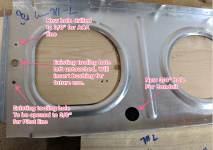

Quick Entry tonight. I’m getting the right wing up to the point where the left-wing is so that I can rivet the skin zone at about the same time. Here’s a time lapse video. I managed to get the right wing skeleton fully dimpled and even managed to remove a … Continue reading