After reading over the plans and instructions last night I decided to get to work today with a clear mind. I completed the Front Spar Assembly section of the empennage section with the exception of deburring, dimpling and priming. I am going to combine as many of the parts as I can and complete these together to save setup time in my priming booth. There is no riveting to be done at this point anyways, so it will work out perfectly.

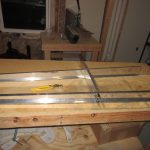

I cleco’d HS-710 and HS714 to the HS-702 spar channels and marked the lines for center line and the bend lines per the plans. Then it was time to do a little fabricating on the spar channel. I cut off the flanges of the spar channel inboard of the bend lines and smoothed the edges. Then I drilled the relief holes and enlarged it to 1/4 on the channels. I only trimmed the angle back just a bit for now until I could measure and cut after the bend was made.

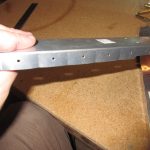

Then I bent the HS-702 spar channels to the exact 6 degrees using my hand seamer and a protractor. They turned out nicely. From there, I re-clecod the HS-710 and HS-714 so I could match drill everything inboard of the bend lines and rib attachment holes.

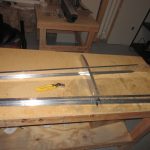

Next I tapered the ends of HS-710 and HS-714 per the detail section of the plans. I used my bench grinder on this part to make it easier. I marked the lines a bit large so I didn’t over-grind anything. Once I got a taper that I liked, I polished the edges off with the scotchbrite wheel so I wouldn’t scratch the spars or my hands. I will finish them off better once I get ready to prime everything. I left some notes in my plans to do this. After the taper was set for them, I measured for my bend lines and then bent them using a vise to the 6 degree angle per my protractor. While the tapers may not be as beautifully done as the pros, I hope they will be OK. They meet the edge distance requirements with some meat left, and they taper nicely along the spar channels and the edges are broken clean. I think thats the only requirements for this to be a safe part. I may ask the folks in the RV-7 sub just to make sure, since I can always trim them down more if I need to before priming.

I am still a bit confused as to how the HS-00001 doublers go into place, but I will read the SB some more and try cleco’ing everything together and lining them up before final prep and assembly. I left a note in my plans to come back to this.

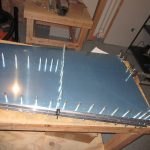

Then I moved on to the last step and that was to countersink the holes needed on the front spar HS-702, HS-710 and HS-714. The plans state that the inner 4 holes must be countersunk from with the flush head facing aft. So, I setup my countersink cage using some scrap and a AN4264-4 rivet to get it at the perfect depth. Then I drilled the 2 center holes on each the HS-710 and HS-714 angle support bars. I used my DRDT-2 dimpler to dimple the light metal of the spar channel then test fit everything back together with clecos. They dimpled parts nestle together very nicely with no gaps. I was happy to close out the front spar assembly section with these results!

Some last few steps: After letting VS-146 dry, I noticed I was a bit light on my primer and missed the bearing housing a little. So I gave it a second light coat with the part on an angle to cover the sides of the bearing housing. I’ll let it dry overnight before assembling it.

The next section of the plans was “preparing the ribs” which was really only two easy little steps, so I figured I would go ahead and knock it out while I was in the mood. I fired up some Blackberry Smoke to listen to, and prepped some metal!

I trimmed both HS-00006 parts making sure to take note of left / right orientation and then marking accordingly. If you are reading this and are on this step, make sure you double check the orientation on the plans!!! After smoothing out the edges I moved on to the others.

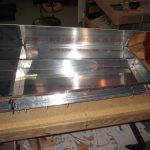

I picked parts (2 each) HS-00005, HS-706, HS-707, and HS-708 from their shelves and removed the blue plastic from them. I have read leaving the blue plastic on parts that will be mated together is not a good thing because it affects your measurements. These are all internal parts that I am going to be scuffing and priming anyways so it wasnt needed anymore. I used a 90 degree straight edge combination square to make sure all the flanges of each part were at a true 90 degrees. Some were pretty good, others needed a little tweaking with my edge seamer. Then I moved on to fluting the parts. These parts are fairly complex punched parts and due to the nature of press punched parts sometimes they are “warped” as slight degree. I laid them on my bench (both sides of them) to check their flatness. If any were not flat, I would make a couple of flutes and re-check, repeating the process until they were laying flat and true. Once I had a part trued and flat I marked its part number in sharpie and laid it back on the shelf. Some parts only needed 1 or 2 flutes, others needed more. I was happy with how they turned out. I will leave the deburring, edge finishing and scuffing until I get ready to bundle all the parts together and prime them.

Here are the photos from tonights work:

https://goo.gl/photos/o96i7MN8sSrisw2H7

Hours Worked: 4.5

Like this:

Like Loading...