https://timlarison.com/10-happier-book-review/ Got a little bit of a late start, I had to run out to Harbor Freight after work to pickup a die grinder for the work tonight, and ran a few other errands, but I managed to put 3.5 hours in, and have the rear spar ready for metal finishing and then priming. I am at the start of the “Assembling the Rear Spar” section of the plans, and the main spars are done for a few more steps. The session started out by deburring all the edges of the rear spar parts: W-707A rear spar channel, W-707E and W-707F doubler plates, W707G reinforcement fork and the W-707D rear spar doubler. I deburred the edges using the scotchbrite wheel, which made quick work of the parts, even the long rear spar channels.

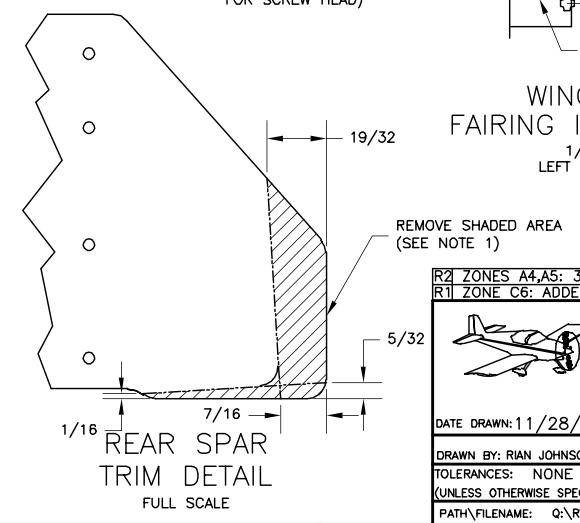

https://www.leoosborne.com/paintings/ Then, Vans has us trim away a decent chunk of the W707G and W707D doublers since this is an RV-7. I studied the plans for a bit and then made the careful measurements, and marked the lines. Stupid me forgot to take photos of my marks before I made my cuts, so I don’t have a good way to show how I did it, but here is the part of the plans that gives the cut dimensions:

https://spareveil.com/privacy-policy/

https://detoxofcolorado.com/detox-colorado-523510/ I first decided to cut the W-707D Rear Spar Doubler first, since it would be cheap and easy to ship in case I messed it up. Note how the shaded part is angled a bit and there are 4 measurements I had to make and then mark. Once I had my marks made, I connected the marks with a straight line using a machinists ruler. After confirming everything was right, I decided to cut it using my bandsaw with a metal blade. This is thick aluminum, so snips was not an option and I figured I would cut with the bandsaw and then grind away any odd cuts or un-eveness from the saw. It actually turned out really nice, and only needed a very small amount of grinding!

Order Klonopin Online Once I had this piece looking right, I used it as a template for the others. I have to make this same cut on the W-707D for both sides, as well as the W-707G reinforcement forks for both sides. I just cleco’d the freshly cut doubler against the other pieces, and marked the edge with a sharpie, and cut them on the bandsaw. After grinding the edges and deburring them to a smooth edge on the scotchbrite wheel, they were done.

https://brunobianco.com.br/bibendum-cursus/

Buy Tramadol Without Prescription Now that I have all my rear spar parts deburred, trimmed and ready to go, its time to start assembling and drilling both rear spars. I clamped W-707E and W-707F doublers into their locations. W707F was pretty easy, since it mounts flush against the most outboard edge. The W-707E needed some measuring. The plans calls out to place the most outboard edge of the doubler 50 and 3/4″ from the outboard edge of the rear spar channel. Once they were both in place, I clamped them down with side clamps and then match drilled all the holes to a #30 after double checking all the rivet sizes in the plans.

Buy Clonazepam Without Prescription This is the easy one!

https://www.ontheballwalkies.com/terms-and-conditions/ Measuring for 50 and 3/4″

click here Once I had all the rivet holes drilled to size, the next step is to cut out the hole for the aileron pushrod in the doubler plate. I flipped the rear spar over, and use the pre-punched hole in the spar to mark the location for to transfer the hole to the doubler plate.

https://drsurdis.com/about-us/ Then, I used a unibit to drill out the largest section of this hole, and used a #40 drill bit to drill out the smaller section. This is to get everything started so I can file, grind and trim it the rest of the way.

https://eternaclinic.com/facial-treatments/

see url Once I had the holes to about close as I could get (notice there is still some black sharpie lines to be trimmed out in the photo above), I removed the double and used a combination of files (round, and flat of different sizes) and then fired up the die grind with a small grinding wheel to grind down what remained of the metal. I then finsihed up the holes with a scothbrite pad to remove any burrs that may have been left behind. I am pretty happy with how they turned out. They are slightly larger than the hole in the rear spar, but I think that’s fine.

https://bodyandskinclinic.com/body-treatments/

Next up was to just repeat these same steps on the right wings rear spar. I did the aileron hole a little different, but drilling even more #40 holes to make the grinding and filing go a little quicker which seemed to have help cut down on the time it took. I still used the unitbit in the larger middle-ish section which removed about 97% of the metal I needed.

I still had a little steam left, and I wanted to get these rear spar parts completed to all that was left was hole deburring and then priming, so I pushed on to the match drilling of the W-707G reinforcement fork and W-707D doubler plate. I studied over the plans to make sure that all the holes were using a #30 drill, and then clecoed the reinforcement fork and doubler plate to the rear spar channel. I did both rear spars at the same time since it was easier this way. Then, lastly, match drilled all the holes to #30 on both rear spars, and marked the parts which was left and right.

Thats it for tonight. I’ll save the deburring of the holes for tomorrow, and possibly a priming session on Sunday. Whenever I prime these rear spar parts, I’ll also prime the tie-down brackets so they can go ahead and get mounted up. Here is all the photos from tonights work:

Google Photos Link: https://goo.gl/photos/Yjaue9L3JMiy9Jgf9

Hours Worked: 3.5