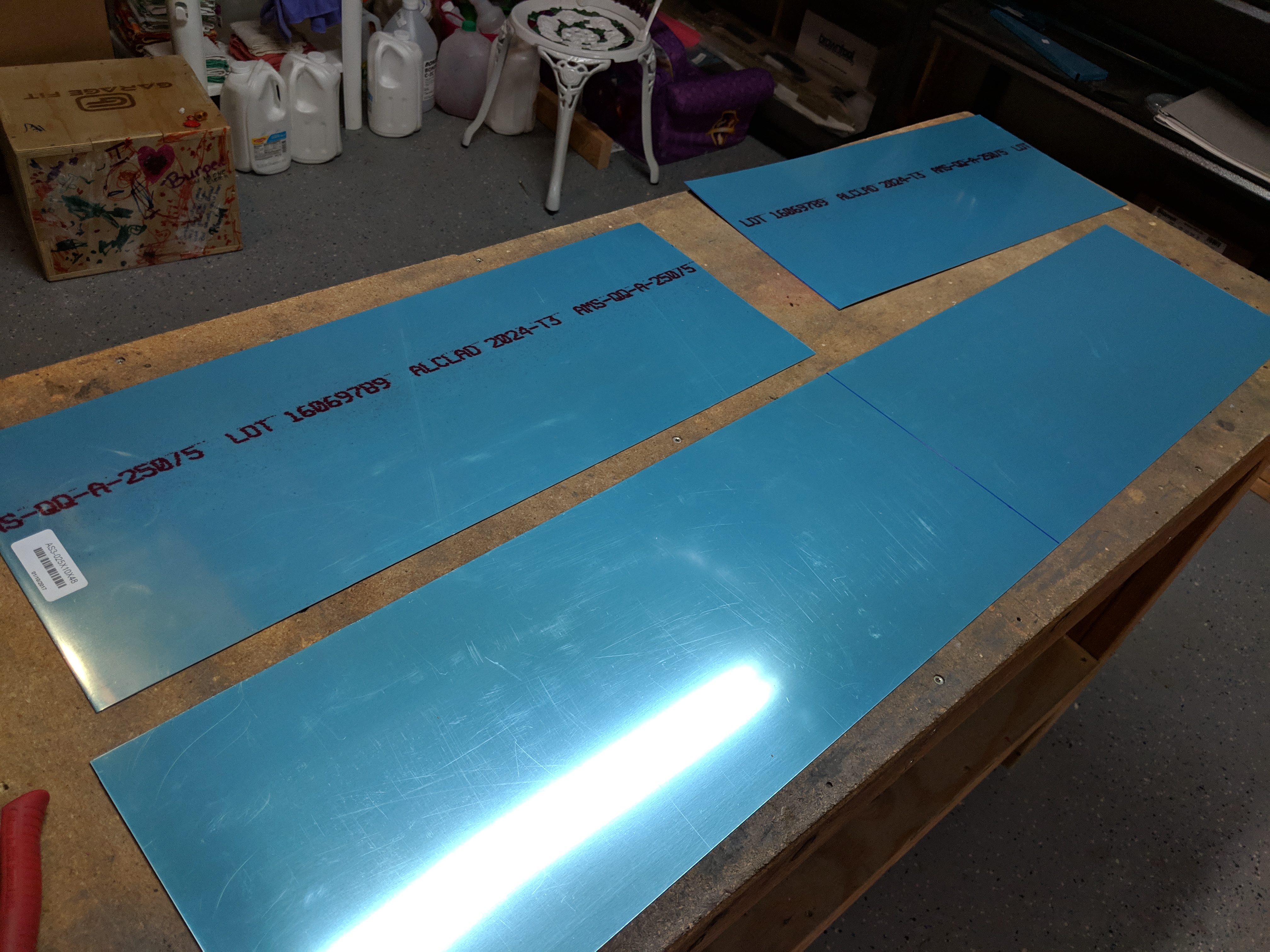

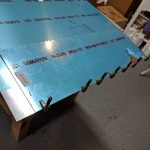

FINALLY! Back to what feels like building again! It’s time to start getting the skins onto the wings. But first, I need to fabricate the wing walk doublers from some provided aluminum sheet. The doublers help support the weight of people walking on the inboard section of the wings to get in and out of the airplane. They are pretty simple, just a piece of .025″ sheet that goes underneath the actual wing skin. Vans tells us to fabricate them using the AS3-025 sheet. The sheet (2 of them) are 10×48″ as shipped by Vans, and the plans calls for us to trim them down to 9 3/8″ x 26″ in dimension. So, I measured out those dimensions and used my aviation snips to trim it to size, for both wings.

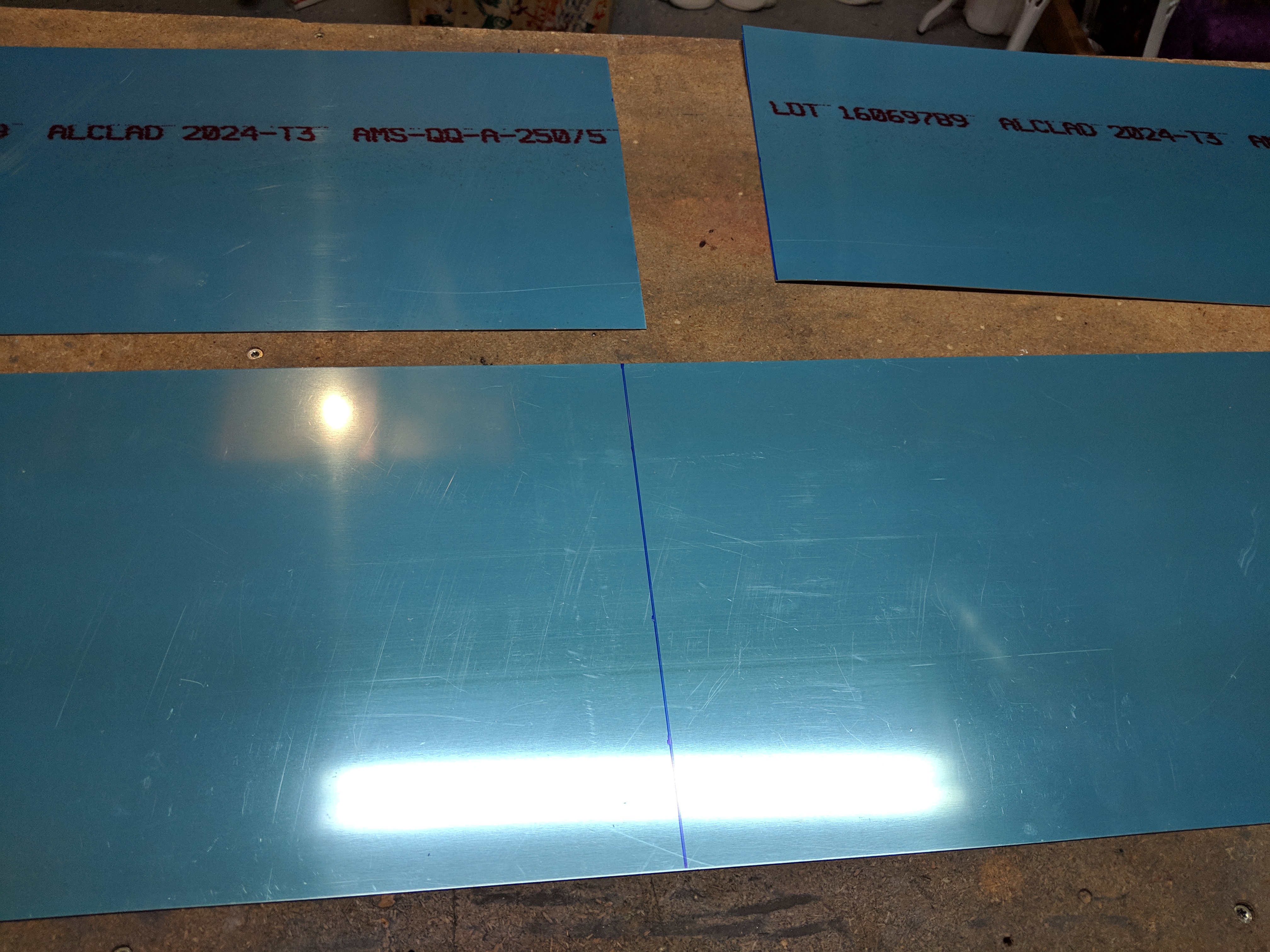

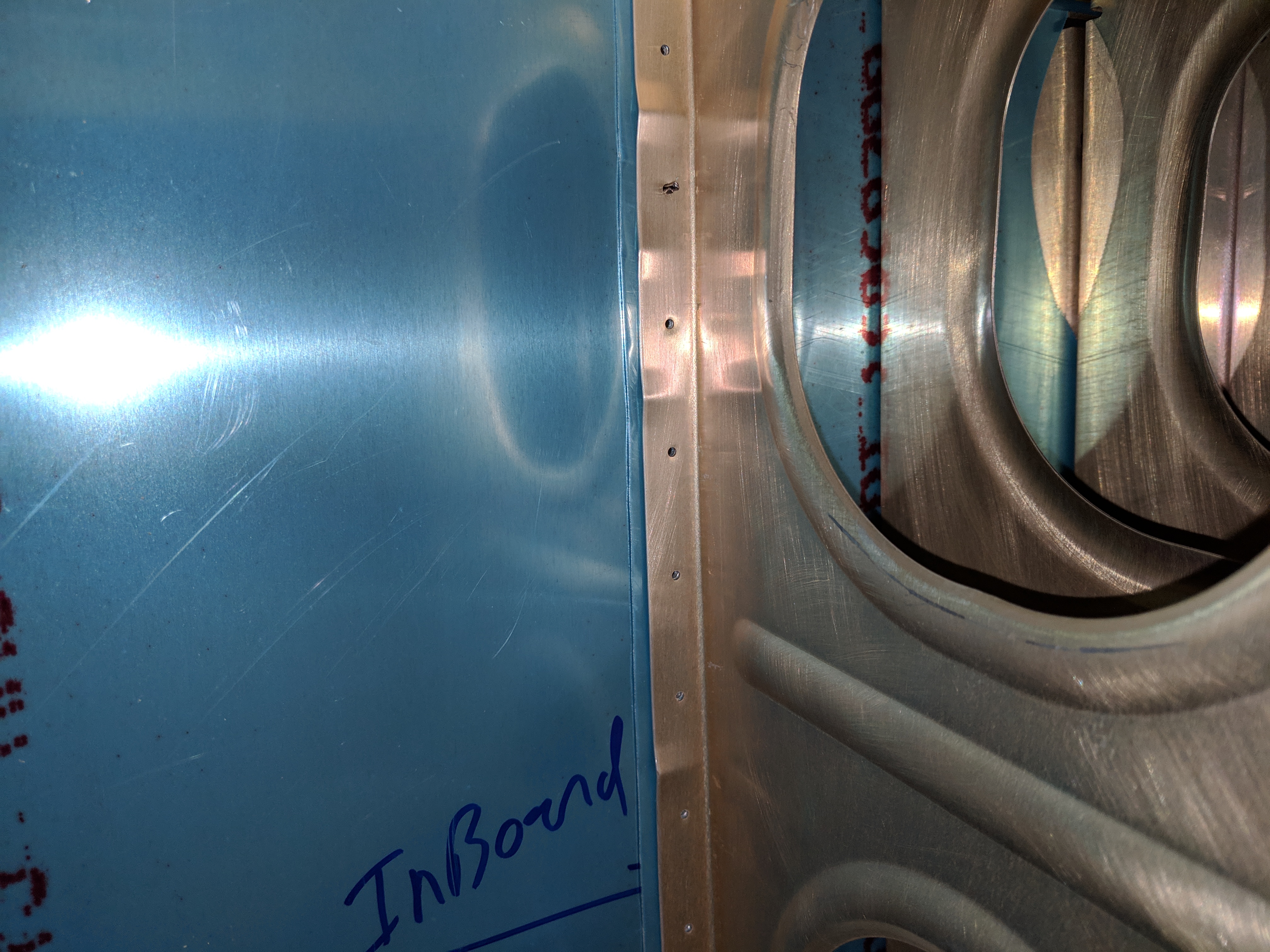

Once we have both sheets cut out, the plans tell us to use the W-702 inboard wing skin as a template to back drill the sheet. So, I lined up the inboard edges of the skins as described in the plans, and made sure to leave the forward edge of the doubler back 9/16″ from the forward edge of the W-702 skin. This is because the double doesn’t need to sit on the main spar at the forward edge, but just almost butt up against it. In the photo below, the AFT edge of the skin is on the left, and the FORWARD edge of the doubler is on the right, you can barely see the 9/16 spacing.

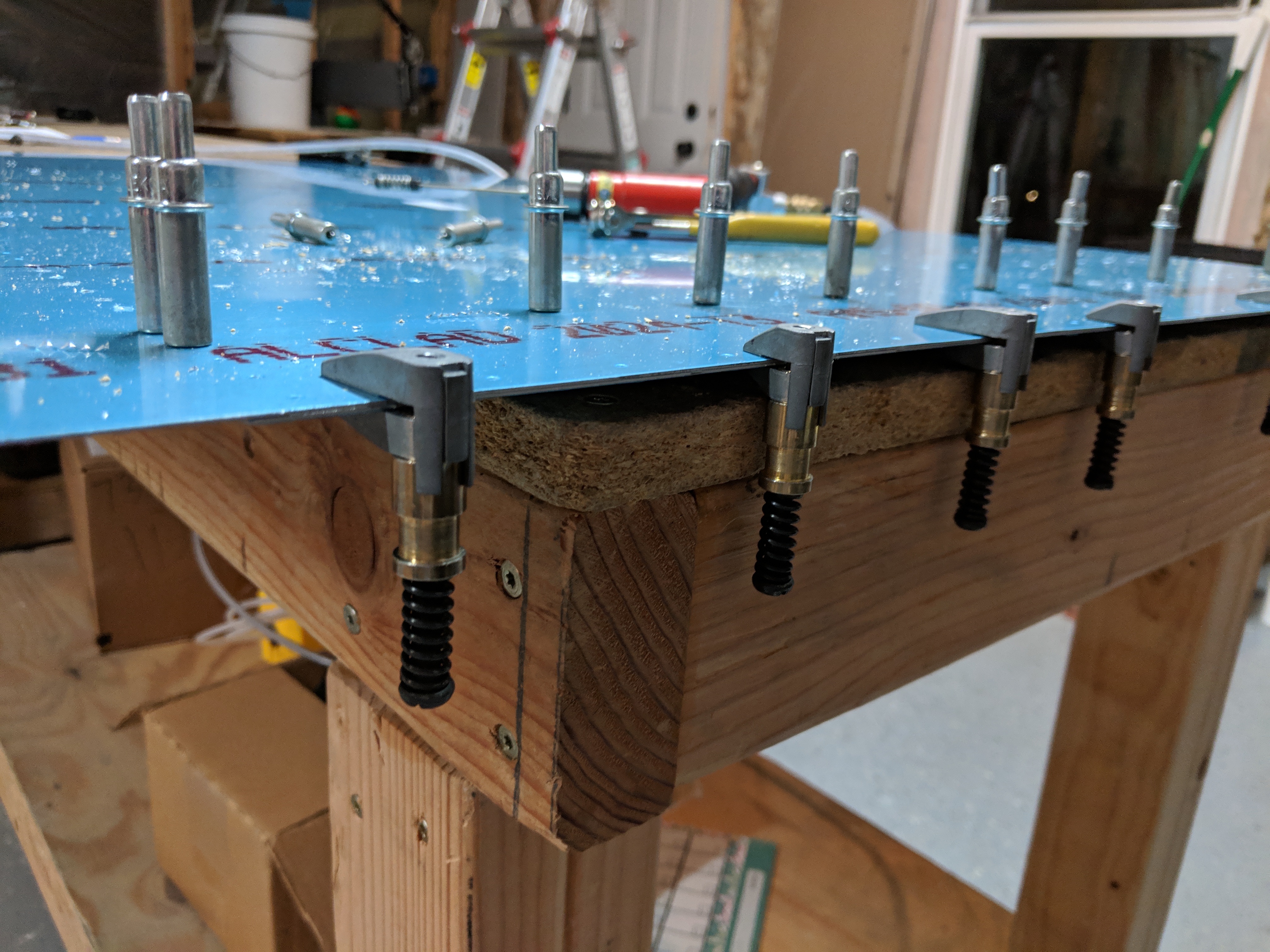

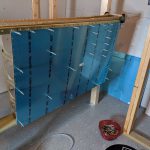

I used the cleco clamps to hold the doubler to the skin, then flipped the skin over (hanging the clamps off the edge of the work bench) so I could back drill on a flat surface. Using the W-702 skin as a guide, I back drilled all the holes for the doubler. Once I had a line done, I use clecos to help hold the skin and doubler together, so that I could finish off the outboard holes.

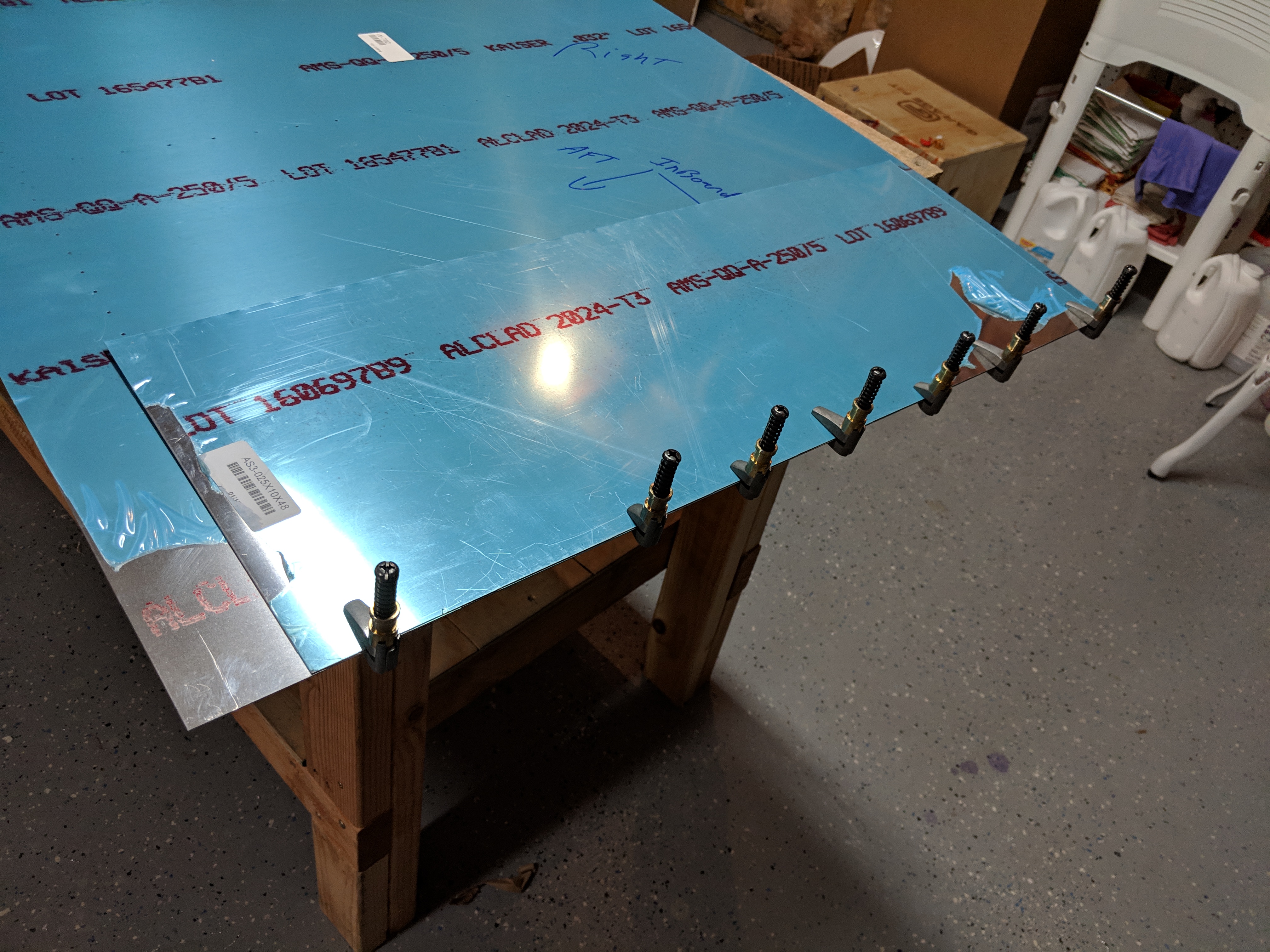

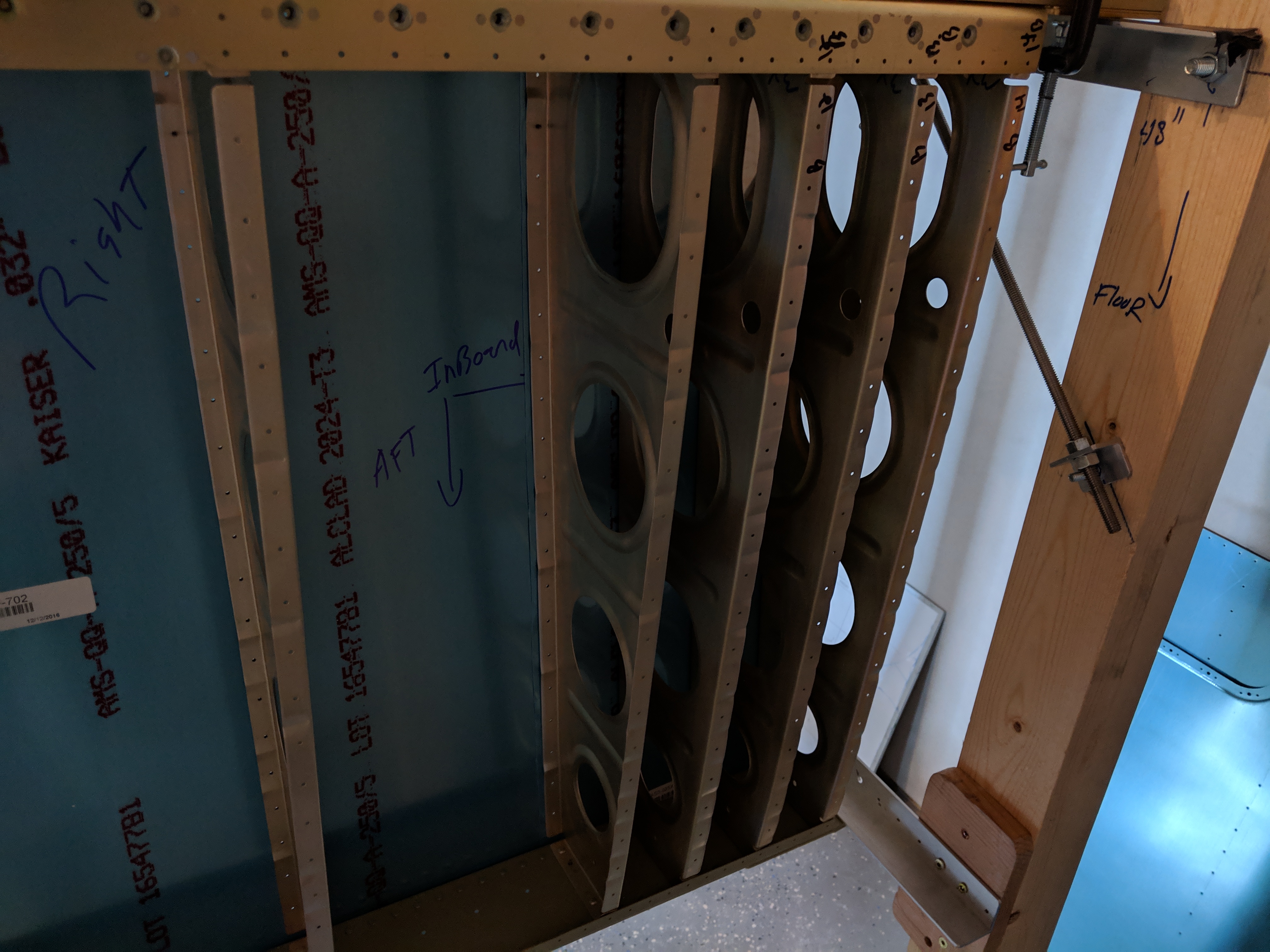

After I had all the holes back drilled into the doubler, it was time to give it a test fit, along with the inboard skin, onto the wing skeleton. I noticed I had to adjust the jack a little bit, as it must have settled some over these past few days. I am going to pick up some high-visibility thing filament fishing line to make sure I have all the holes perfectly aligned before I start match drilling these skins. So, tonight I just wanted to test fit them with the newly fabricated doublers.

The doublers seem to fit pretty good, there is a slight overlap as you can see in the photo above, but that seems to be no problem. I do think I have the correct amount of overlap on the rear spar as well. Here’s a photo album from all of tonights work. I did both the left and right wings doublers and skins, but didn’t take photos of each side, because….they are pretty identical.

Google Photos Link: https://photos.app.goo.gl/qfi5ka73wZXodm2P9

Hours Worked: 1.75 hours