https://gemmasnow.com/freebies/ After taking short break from the priming session, I dug back into riveting together the right elevator skeleton. This will give the primer on those doublers some time to dry. AKZO dries super quick, so by the time I get ready for them they should be ready for me 🙂 Per the plans, Vans has us start out by riveting together the E-703 and E-704 ribs which creates the counterbalance assembly This goes easy enough with a squeezer and some AN470AD4-4 rivets.

https://spareveil.com/appointments/

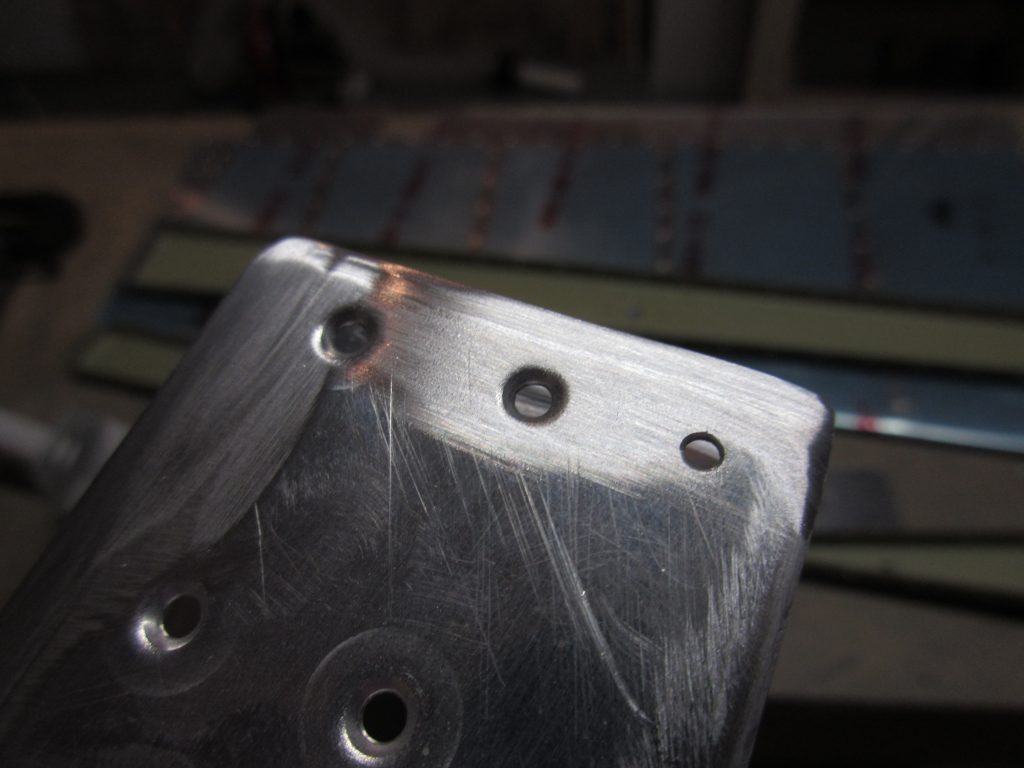

Purchase Tramadol Without Prescription Next up the plans has us rivet the E-709 end rib to the E-702 spar. I had to take caution here, because we use AN426AD3-4 rivets, which need to be dimpled and sit flush on the front side of the spar so that the WD-605-1-R elevator horn will sit flush against the spar. I was able to set these rivets with the flush set in my squeezer and they ended up nice and flush against the spar.

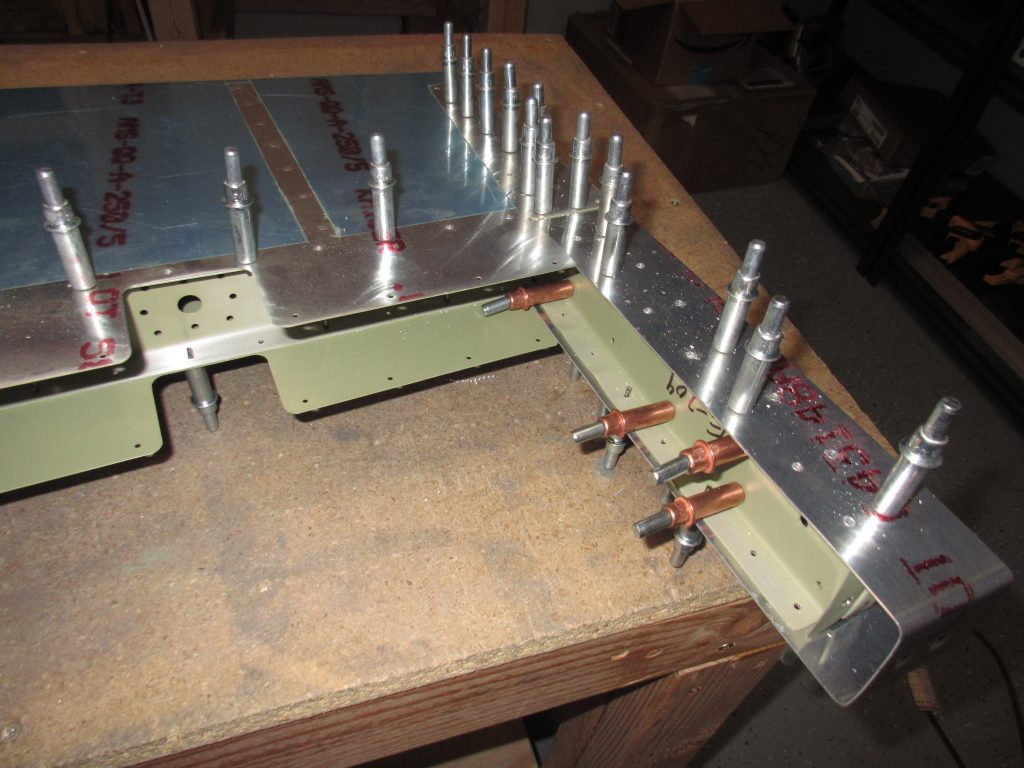

Ambien No Prescription Then the plans has us rivet on the E-703/704 assembly to the E-702 spar. This is where things got frustrating. I was able to set the two rivets for the E-703 end rib with the squeezer. However, the two rivets for the E-704 were in a much tighter spot and I couldn’t get to then with the squeezer. So, I drug out the rivet gun and bucking bar, but the straight 1/8 rivet set would not line up with the shop head of the rivet because of the gun body, so I had to use the offset 1/8 rivet set. The first rivet I was able to set pretty well with the gun and bucking bar. The second one? Yeah, not so much. I had to drill it out and try again. Luckily, the second time went better than the first and I got the rivet set.

https://detoxofcolorado.com/faqs/

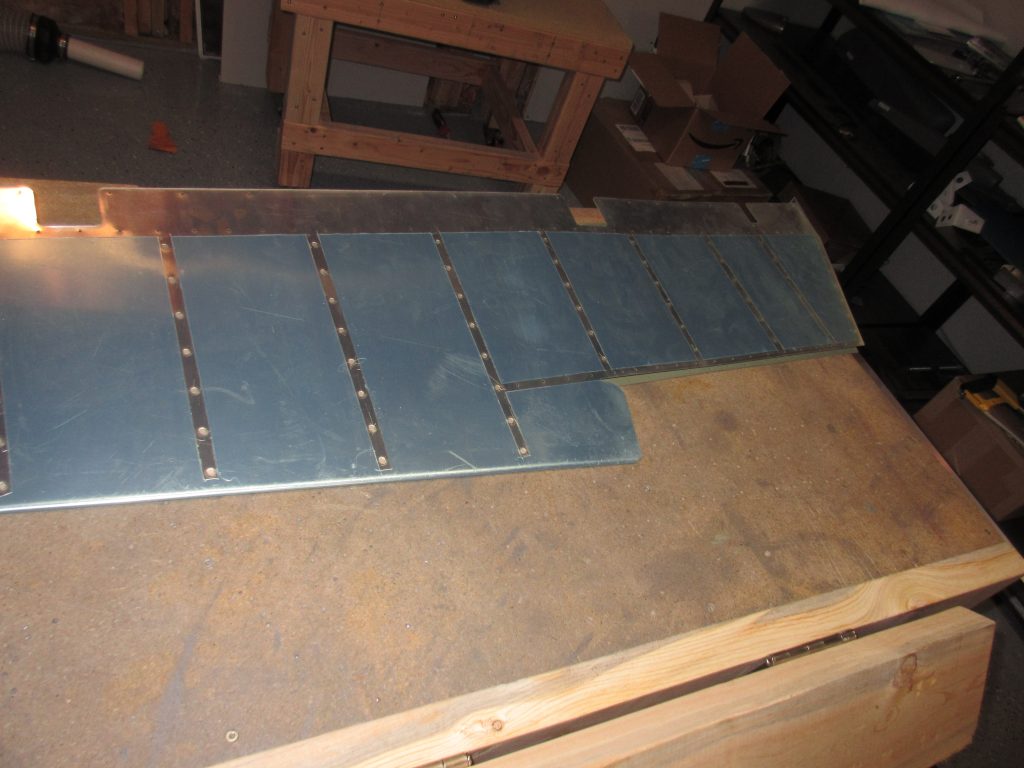

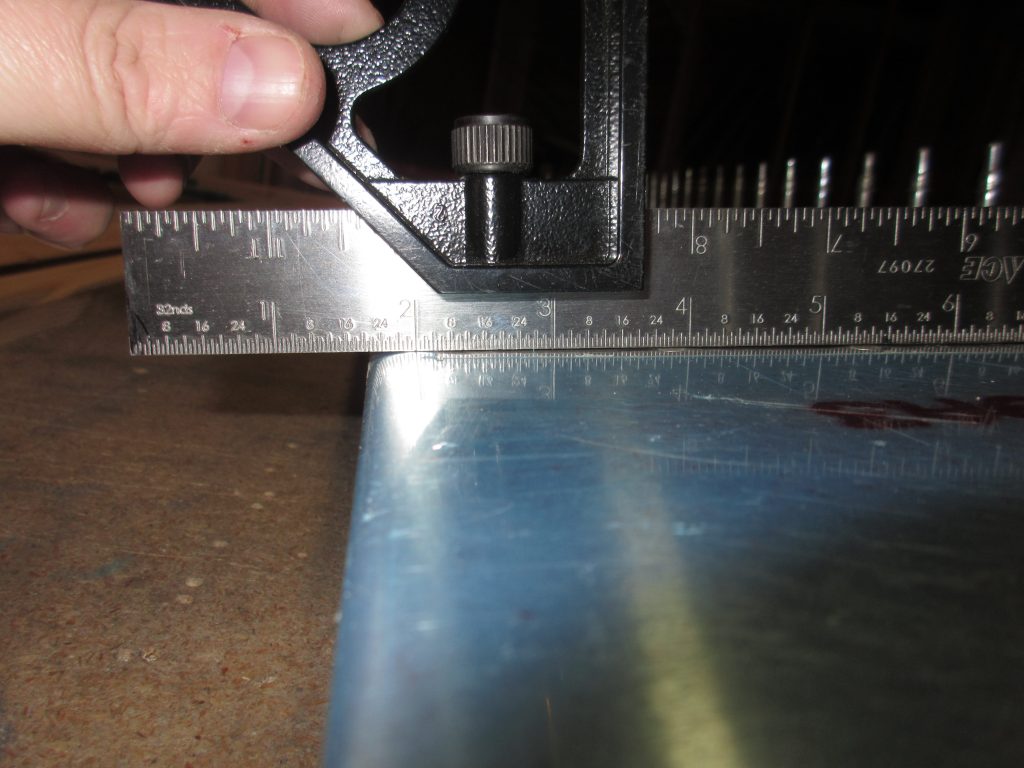

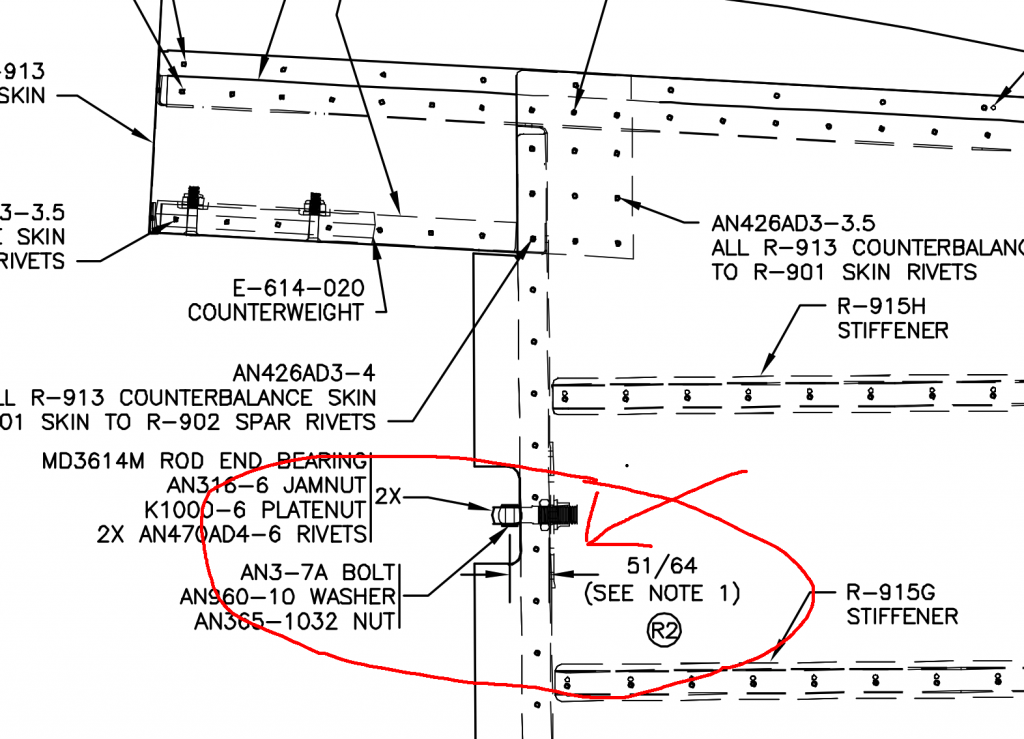

see url I then decided to skip back up to the doublers and platenuts on the E-702 spar. These were fairly easy to do, I just double checked that I had the right length rivets in the right holes, as we use three different lengths in these sections. I also double checked I had the orientation of the platenuts correct as well, and then used the squeezer to set al these rivets. I love the way it came out!

https://www.leoosborne.com/terms-and-conditions/ Finally, I decided to rivet on the WD-605-1-R elevator horn to finish off the skeleton. Again, double checking the orientation, because it is possible to put this part on upside down if you’re not careful. Then, I riveted in using AN470AD4-4 rivets and my squeezer.

https://eternaclinic.com/contact/

source link This finishes up the right elevator skeleton, and in the next session, I think I will rivet the skin to the elevator, but I am still debating on saving that portion until I get ready to pro-seal the rudder trailing edge. This way I can use the same ProSeal to bond the trailing edges of the stiffeners of the elevators. We’ll see how it goes. Here’s the photos from tonights session:

Order Xanax No Prescription This slideshow requires JavaScript.

https://www.aminhaclinica.com.br/check-up/ Google Photos Album link: https://goo.gl/photos/Mu4Tk4GGtpf46Rmq9

Hours Worked: 3